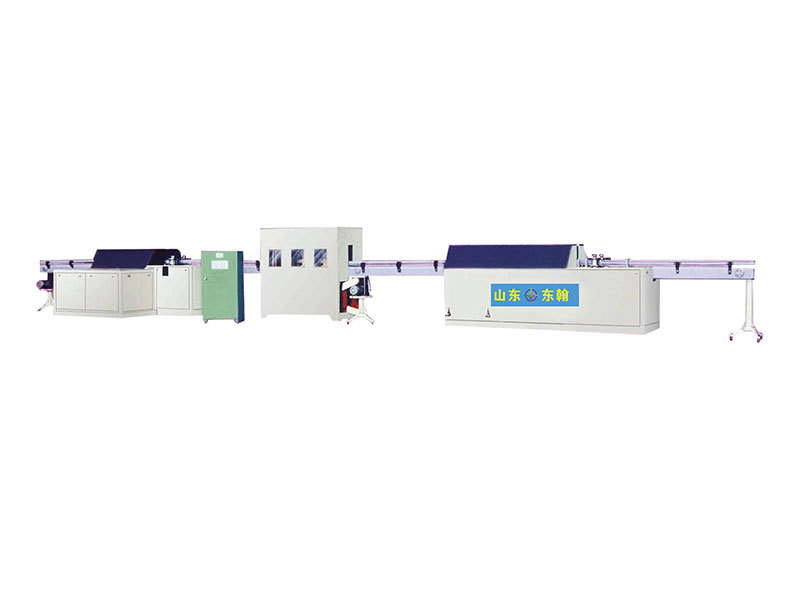

GFY24/6 conjoined filling and capping machine

Classification:

GFY24/6 type filling and capping machine is a kind of high efficiency

Key words:

GFY24/6 conjoined filling and capping machine

Product Description

GFY24/6 type filling and capping machine for automatic rotary filling, automatic capping combination, is a kind of high efficiency of automatic liquid packaging equipment. Small size, high production capacity, saving space and investment. Mainly suitable for non-steam liquids (such as alcohol, beverages, food spices, pesticides and other liquids) filling and sealing process.

Performance characteristics

Due to the combination of filling and capping, the production process is shortened and the probability of external contamination of the liquid is reduced. The machine by advanced programmable (PLC) automatic control operation, photoelectric detection of the operating conditions of the components, with high automation procedures, easy operation and so on.

2. When filling liquor, the filling machine adopts measuring cup type quantitative filling, numerical control stepless volume adjustment, all filling valves can be adjusted synchronously, the capacity range can be adjusted arbitrarily in 120750 ml, and the quantitative accuracy is high. Each filling valve is equipped with a fine adjustment system, which is used for micro adjustment of a single filling valve during overhaul. When filling condiments, negative pressure and low vacuum gravity filling is adopted, the filling speed is fast, and the liquid level is accurate and consistent.

3. The capping unit adopts the advanced technology automatic capping system, equipped with (optional bottle cap lifting machine) automatic capping device, with high degree of automation and good capping quality. With automatic overload protection, automatic control bottle cap out of the lid speed. It has automatic cap supply, automatic cap management, smooth cap delivery, no bottle and no cap supply, photoelectric detection is provided at the cap delivery slide, the cap management device automatically starts to run when there is no cap, and the cap management device automatically stops when the cap is full, thus ensuring that the cap is not damaged.

Number of main technical dreams

1. Number of filling heads: 24

2. Number of gland heads: 6

3. Production capacity: ≤ 6000 bottles/time

4. Adapt to bottle type:

Bottle diameter: φ60-90mm

Bottle height: 150-300mm

5. Speed regulation mode: variable frequency stepless speed regulation

6. Motor power: 2.2kw

7. Overall dimension: 2000×1650×2480mm

recommend products

Welcome your message consultation

-

Our staff will contact you within 48 hours (working days). If you need other services, please call the service hotline:+86-536-2260988