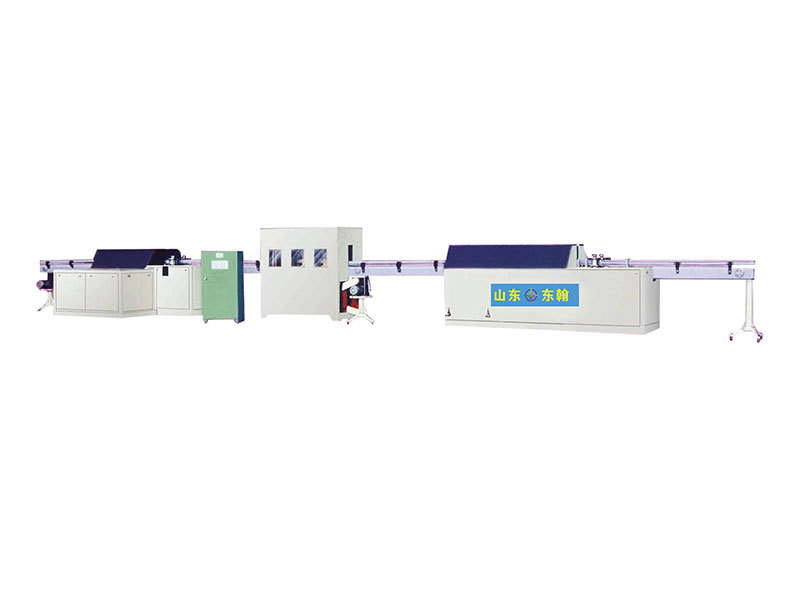

GZD in-line filling machine

Classification:

GZD type in-line filling machine adopts linear structure for filling.

Key words:

GZD in-line filling machine

Product Description

GZD type in-line filling machine is mainly suitable for soy sauce, vinegar, wine, beverages and pesticides and other non-gas liquid automatic packaging production line, the machine adopts linear structure filling, in addition to adapt to circular packaging containers, but also adapt to square and other special-shaped bottle packaging, while using electronic quantitative, programmable control, so the operation is simple, accurate measurement. The machine is widely used in all kinds of bottles, barrels for liquid packaging process, is the ideal packaging equipment for liquid packaging manufacturers.

Performance characteristics

(1) the bottle to adapt to a wide range: because the equipment adopts in-line principle, the bottle with the conveyor belt into the bottle, so not only suitable for round bottles, but also suitable for square bottles and other special-shaped bottles.

(2) high filling precision, fast speed: because the machine adopts electronic quantitative filling, man-machine interface touch screen control, convenient and quick to ensure the filling accuracy and filling speed.

(3) Anti-foaming design: As the machine adopts "submersible" filling valve device, starting from the bottom of the container and automatically lifting the two-step filling, it effectively prevents the possibility of liquid splashing and foaming during filling.

Anti-drip system

Because the machine uses a special negative pressure automatic control system, when the end of the filling in the filling head to form a negative pressure in the filling head to absorb the adhesion of the liquid, so as to prevent the liquid drip.

The filling liquid is pressed into the liquid storage cylinder by the water pump (or high liquid level tank), and the liquid level in the cylinder is controlled by the liquid level sensor to effectively maintain the stability of the liquid level in the liquid storage cylinder.

Number of technical dreams

1. Filling station: 6 heads, 8 heads, 10 heads, 12 heads

2. Filling capacity: 1200~5000ml

3. Production capacity: 800-3000 bottles/hour

4. Adapt to bottle type: round, square and various special-shaped bottles

5. Adapt to bottle height: 150-280mm

6. Adapt to bottle diameter:<150mm

7. Inner diameter of bottle mouth:>26mm

8. Use air pressure: 0.4-0.7mpa

9. Filling accuracy: 1%

recommend products

Welcome your message consultation

-

Our staff will contact you within 48 hours (working days). If you need other services, please call the service hotline:+86-536-2260988